This technical note gives guidance on the selection and specification of circulation pumps, including variable speed drives. It incorporates information from the 2017 PWTAG book Swimming Pool Water.

The right pump for the application

Pools should have sufficient pump volume/head capacity to achieve the required pool turnover period even as the filters become dirty. And they must take into account any extra processes such as secondary disinfection – UV and ozone and the pool heating system. Most secondary disinfection systems operate at full design flow. They will not operate at substantially reduced flow and should be bypassed if flow is reduced to the critical level. In that case, the pool is not operating as it is designed to in terms of disinfection and filtration. This substantial reduction in performance efficiency will need to be considered by the pool operator and its consequences taken into account.

Standby pumping capacity should be provided in a public pool to allow the plant to continue to function at full flow if one of the pumps has failed. The pumping system should be capable of reduced flow rates at night when appropriate.

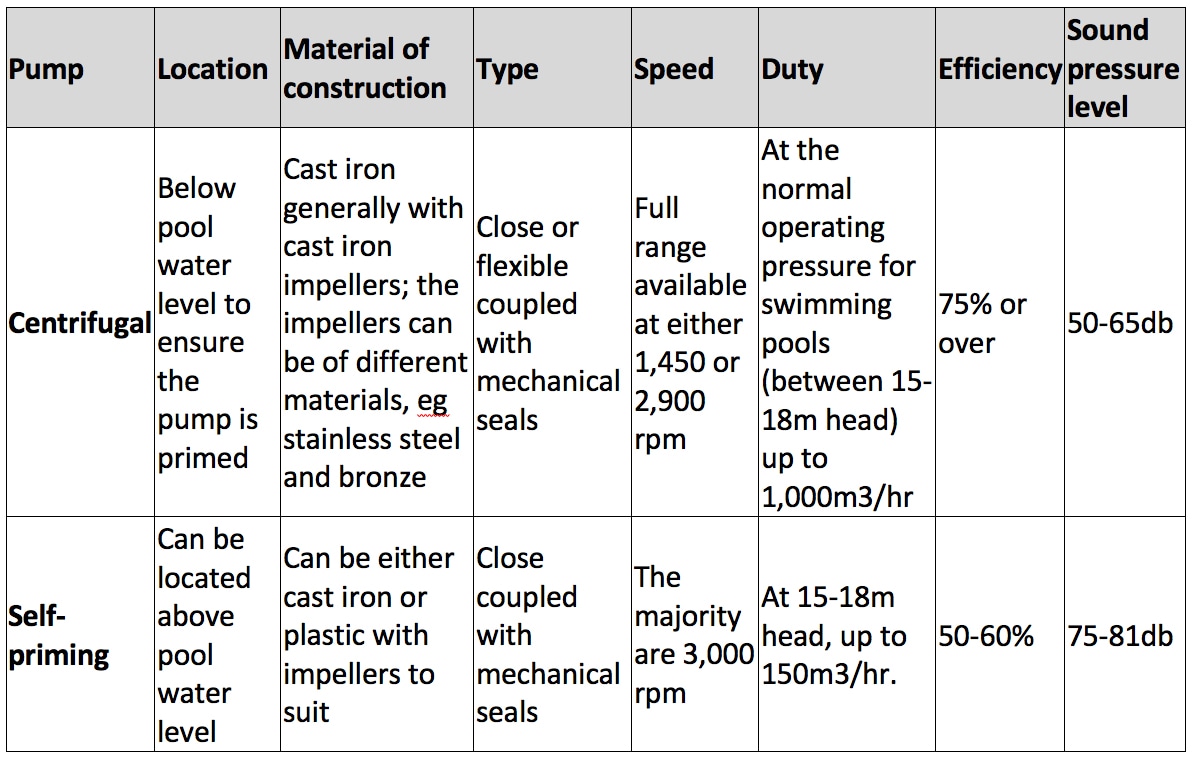

The pumps and their layout should be designed in accordance with the manufacturer’s recommendations, and their performance guaranteed. Most systems use standard centrifugal pumps, but the table below gives a detailed comparison with the other type – self-priming pumps.

In summary, centrifugal pumps have a longer life span and are quieter. Their greater efficiency could typically save a pool £5,000 a year in running costs; double that in a leisure water complex, due to typically higher flowrates. Although self-priming pumps require no pump pit, the cost of providing a pump pit is far less than the increase in running costs for a centrifugal pump.

Variable speed drives (VSDs)

The rationale for incorporating variable speed on swimming pool circulating pumps is to enable the circulation rate to be reduced overnight and during low bathing load periods, in order to reduce power consumption. The flow through filters should not be varied too abruptly because it will unsettle the bed and could cause suspended particulate matter to be forced through the bed into the pool. Incorporating variable speed control provides a secondary benefit in that the filter backwash rate can be set to ensure that the filters are always backwashed at the correct rate.

There must be enough surplus capacity in the system to allow for the reduction in turnover involved with VSDs. For example, it should have been demonstrated by chemical and bacteriological monitoring (through busy periods over 6 to 12 months) that it has the surplus capacity. If it cannot, PWTAG recommends that VSDs should not be contemplated

A typical installation cost for a variable speed drive is £3,000; annual energy savings might be £1,000.

Before deciding on variable speed, these factors should be considered:

- The swimming pool water volume should be circulated at least twice and preferably three times when the pool is not in use.

For competition pools this is likely to result in a maximum reduction in circulation rate of 20 to 40 per cent. For small pools where the turnover period is short, the reduction could be 50 per cent or more. The circulation rate should not be reduced by more than 50 per cent as this would affect free chlorine and pH control. If the circulation rate is reduced during low bathing load periods then the chlorine and pH levels should be regularly and closely monitored. - Reducing the circulation rate should never be allowed to affect the percentage of surface water being extracted from the pool – particularly important on a deck-level pool.

- Most pH and chlorine controllers require a steady flow rate for the readings to be accurate. Commonly the sample point for the controller is after the circulation pump, relying on the pump for a steady flow. When the pump speed is reduced, less water flows through the sample cell and this can lead to inaccurate controller readings and/or locking out because of low flow. The controller should be checked whenever the flow rate is altered and the flow adjusted as necessary. In some instances a separate pump can overcome the low flow problem.

- Similarly, many pool dosing systems (eg circulation and erosion feeders) rely on dosing at a certain circulation flow rate. This applies to PAC dosing and day tank feeders, particularly those using venturi or differential pressure

Pump efficiency and operation

In most pools, the pumps do not have a positive suction pressure and there is not a positive pressure at the pump suction in operation. There are three factors that can reduce the efficient operation of a circulation pump – air entrainment, cavitation and incorrect hydraulic design.

- It is essential that the suction pipework has no areas where pockets of air can be trapped, for example in raised loops or at the point where pipework size changes. Most pumps are fitted with a suction strainer box and it is an essential requirement with centrifugal pumps that the top of the strainer box is above the level of the suction pipework to allow venting prior to the pump being put into operation. The most likely points for air to be drawn into the system are the strainer box lid valve seals.

- Cavitation happens in a pump when the pressure on the suction side is lower than the vapour pressure of the liquid. Small vapour bubbles form and then collapse (implode) as the pressure rises, releasing shock waves which can damage impellers. Cavitation decreases the flow and head, which in turn leads to reduced pump performance.

- The most efficient pumping systems incorporate two full duty pumps, one on standby. They should be rotated in use so neither pump stands idle for long. Alternatively, three 50 per cent duty pumps also allow one standby; this may have to be considered where the pump has limited duty, eg a self-primer. There are numerous disadvantages though – more cost, more equipment to maintain, more space needed, and at least seven per cent more running costs.

- Subject: Swimming Pool Circulation Pumps and Variable Speed Drives

- Date: July 2020

- Download Print Version: Technical Note 49 PDF